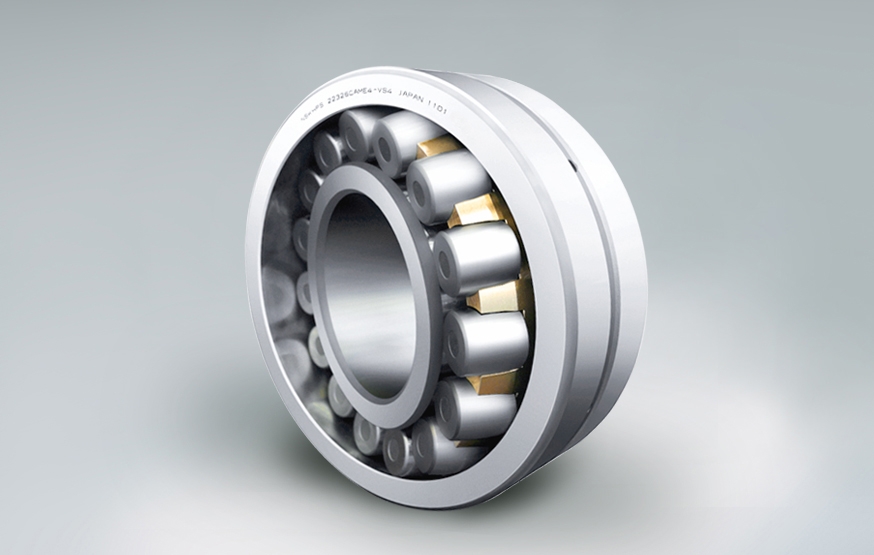

A customer in the QM industry was experiencing premature failure of cylindrical roller bearings used on vibration units for a block vibrator machine every 2-3 Months. The bearings run in a very harsh environment exposed to contaminants, heavy vibration and shock loads. The impact was increased maintenance and costly downtime. NSK proposed Spherical Roller Bearings VS series and supervised the fitting of the bearings – which outperformed over 12 months, reducing maintenance and associated downtime.

| Before | Cost p.a. | NSK Solution | Cost p.a. | |

|---|---|---|---|---|

| Bearing Costs | € 9 239 | Bearing Costs | € 2 310 | |

| Engineering Costs | € 1 065 | Engineering Costs | € 118 | |

| Costs of lost production | € 56 798 | Costs of lost production | € 0 | |

| Other Costs: Shaft Inspection | € 10 236 | Other Costs | € 177 | |

| Total Costs | € 77 338 | € 2 606 | ||

Reference:SS-E-2-907