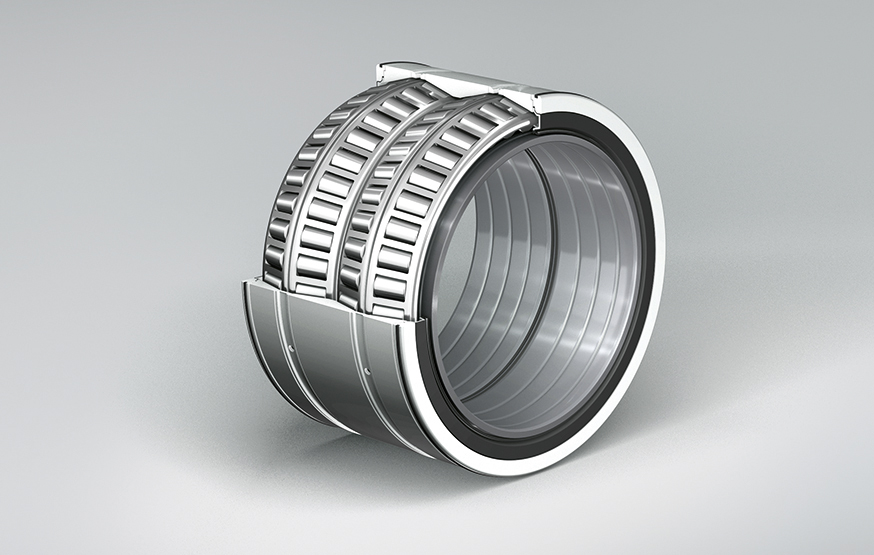

An Indonesian steel mill company was using competitor’s OEM bearings, but the expexted lifetime of the bearings was too short. The Customer decided to try NSK's 4-row tapered roller bearings which performed 2 times longer than those of the competiton. The End user was very satisfied with NSK bearing’s performance because the longer lasting bearing not only saved them more money during production but also reduced machine downtime.

| Before | Cost p.a. | NSK Solution | Cost p.a. | |

|---|---|---|---|---|

| Bearing Costs | € 63 277 | Bearing Costs | € 49 754 | |

| Engineering Costs | € 13 587 | Engineering Costs | € 0 | |

| Total Costs | € 76 864 | € 49 754 | ||

Reference:SS-E-16-888