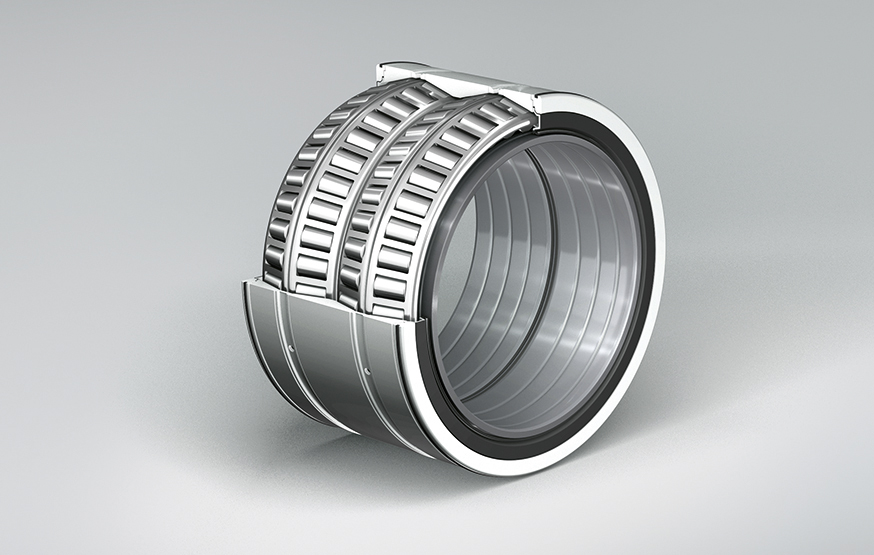

A large manufacturer of steel wanted to increase replacement intervals for 4-row Tapered Roller Bearings used in the hot strip mill. Due to severe operation conditions, standard bearings provided 1.400 hours of operation. The key target was to decrease spend on bearings and costs for bearing replacement and maintenance.

NSK checked the bearing units and the operating conditions. As a result new 4-row bearings with modified internal design and contact angle were delivered for testing. New bearing lifetime was increased up to 2.200 hours.

| Before | Cost p.a. | NSK Solution | Cost p.a. | |

|---|---|---|---|---|

| Bearing replacement costs | € 432.000 | Bearing replacement costs | € 288.000 | |

| Additional maintenance costs compared to NSK solution | € 10.000 | Reduced maintenance time and no additional costs | € 0 | |

| Total Costs | € 442 000 | € 288 000 | ||

Reference:SS-E-33002