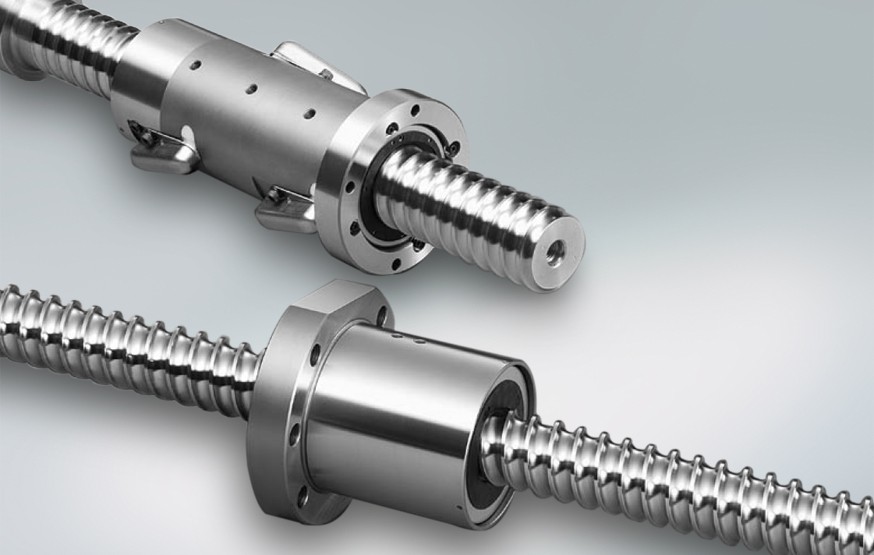

A Tyre manufacturer was having high replacement costs due to frequent ball screw failure in the air drum of a tyre building machine. This was a costly problem with increased maintenance and downtime affecting productivity. NSK analysed the problem and found that the quality and specification of the existing ball screw was not sufficient for the loads within the machine. By introducing a higher specification NSK Ball Screw life time was extended, increasing uptime and efficiency whilst reducing unplanned failures.

| Before | Cost p.a. | NSK Solution | Cost p.a. | |

|---|---|---|---|---|

| Ball Screw pieces per year | €151.212 | NSK Ball Screw pieces - New design helps reduce purchases by nearly two thirds per year | €52.084 | |

| Total Costs | € 151 212 | € 52 084 | ||

Reference:SS-E-0014