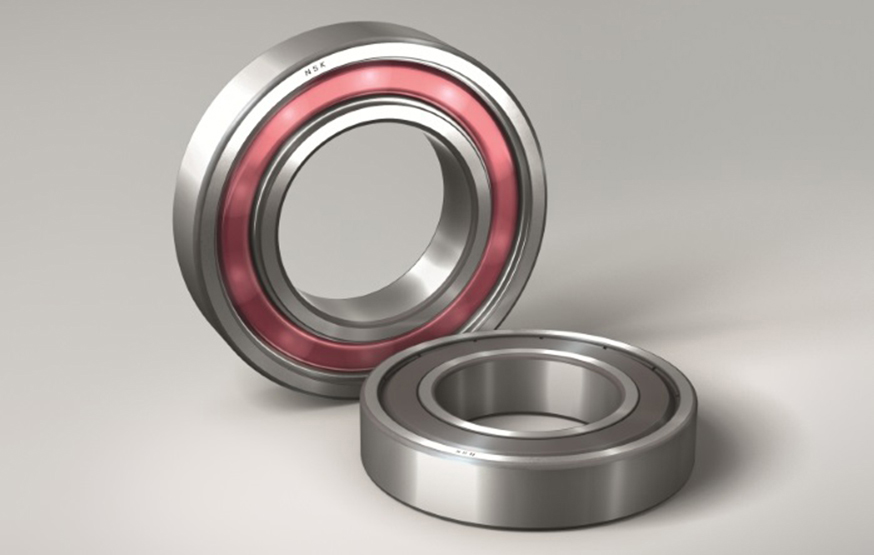

A premium snack processing company was experiencing frequent bearing failures on a potato wash application causing significant downtime and reduced production. NSK carried out a bearing failure analysis revealing ingress of contamination

leading to significant reduction in life time. NSK was asked to find a solution to this problem in order to improve service life. A trial was agreed which resulted in an increase of bearing life by 2 times.

| Before | Cost p.a. | NSK Solution | Cost p.a. | |

|---|---|---|---|---|

| Engineering costs | € 2.500 | Engineering costs | € 250 | |

| Lost of production | € 20.000 | No modification necessary | € 0 | |

| Total Costs | € 22 500 | € 250 | ||

Reference:SS-E-1016