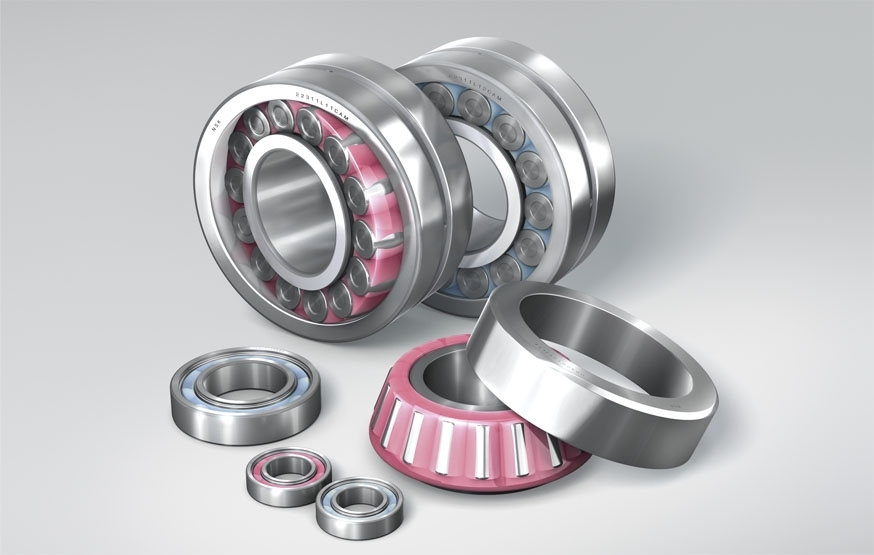

A large producer of fish products was experiencing repeated failures on their Scraped Surface Heat Exchangers. They were changing bearings every 8 weeks which involved high maintenance costs and a lengthy machine down time. NSK investigated this problem and found that and hard contaminants were entering the bearing causing failure. They proposed a trial with NSK Molded-Oil bearings which resulted in immediate improvement and significant lifetime extension.

| Before | Cost p.a. | NSK Solution | Cost p.a. | |

|---|---|---|---|---|

| Previously used Ball Bearings | € 300 | NSK Molded-Oil Deep Groove Ball Bearings | € 225 | |

| 12 failures à 5 hours downtime: 60hrs à 1.250€/hour | € 75.000 | No downtime | € 0 | |

| 12 failures à 5 hours maintenance: 60hrs à 62,5 €/hour |

€ 3.750 | No labour costs | € 0 | |

| Mechanical Seals x 12 | € 18.750 | Mechanical Seals x 1 | € 1.562 | |

| Total Costs | € 97 800 | € 1 787 | ||

Reference:SS-E-2053