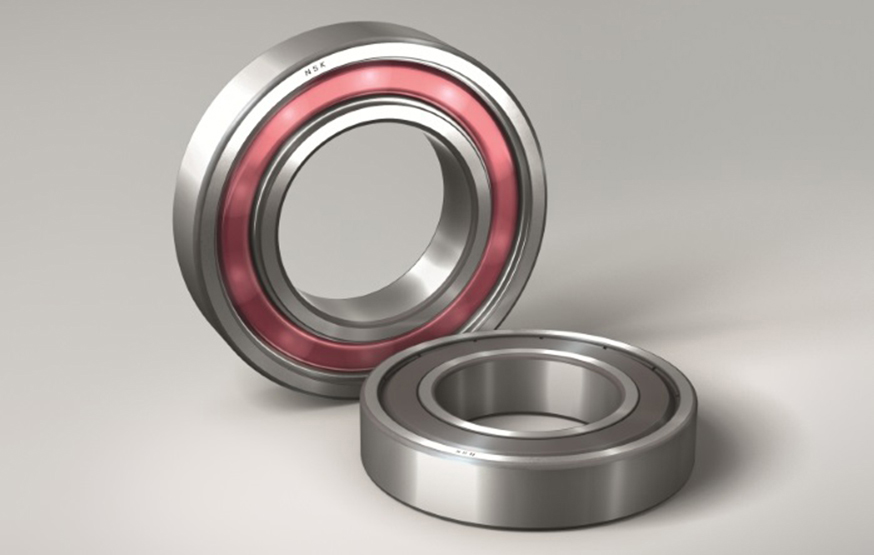

A Snack Foods Manufacturer in the UK was experiencing short service life of only 4 months from standard Deep Groove Ball Bearings, used within a 7 lane food processing conveyor system. Due to daily wash-down cycles, water ingress into the bearings caused premature failure. This resulted in costly maintenance, loss of production and damage to ancillary equipment including conveyor belts. NSK engineers reviewed the bearing application and recommended the use of Stainless Steel bearings fitted with Molded-Oil lubrication and DDU seals, which are designed to perform well in wet applications. Regular monitoring of the application showed that the bearing lifetime was extended to 12 months, which represented a significant improvement.

| Before | Cost p.a. | NSK Solution | Cost p.a. | |

|---|---|---|---|---|

| Deep Groove Ball Bearings Bearings replaced 3 times per year |

€ 684 | Stainless Steel Molded-Oil Deep Groove Ball Bearings replaced once annually |

€ 4.253 | |

| Engineering costs: 2 men @ 35/h each x 24 hours x 3 times per year |

€ 3.218 | Engineering costs: 2 men @ 35/h each x 24 hours x 1 times per year |

€ 1.073 | |

| Potential lost sales profit: €1.276 per hour x 14 hours downtime x 3 times per year |

€ 53.627 | Potential lost sales profit: None |

€ 0 | |

| Total Costs | € 57 529 | € 5 326 | ||

Reference:SS-E-2055