NSK Bearings for the Petrochemical Industry

The machine components used in this sector – such as pumps, compressors, electric motors, blowers and ventilators – are particularly susceptible to change. These components contain bearings which have to work reliably and precisely, even in challenging conditions.

Our Application Engineers are in touch with the research and development teams at OEMs and have the expertise to work with you on developing solutions that effectively cut costs and boost productivity.

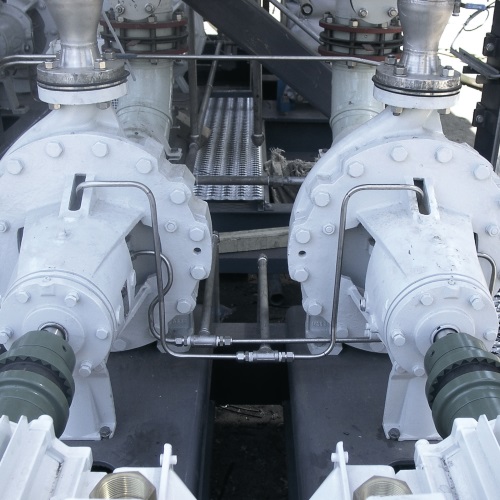

Pump applications place a great deal of strain on bearings, meaning that the materials used for bearings and bearing cages have to withstand tough conditions.

The bearings have to support axial, radial or combined loads, run equally reliably at low and high speeds (1,500 rpm to 3,000 rpm) and handle different lubrication conditions with ease.

The double-row angular contact ball bearing must withstand axial and radial loads, while the deep groove ball bearing is only subject to light radial loads.

It is important to avoid creep (relative motion) between the outside diameter and housing of the top bearing.

Liquefied natural gas (LNG) pumps are used to load/unload cryogenic liquids in tanks.

The bearings used here must be able to withstand a liquid gas temperature of −162°C and are partly lubricated by the pumping medium.

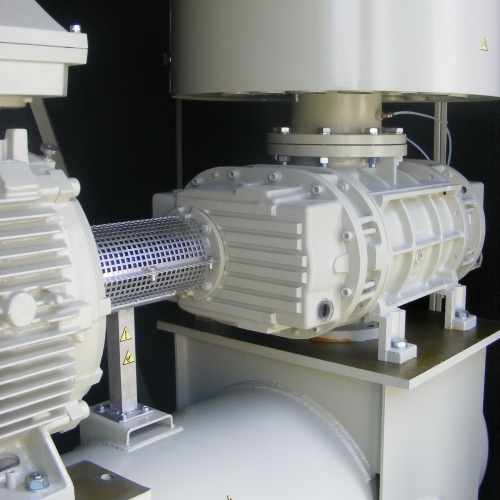

Roots blowers are rotary piston blowers which are often used to transport gas. The gas is carried from the intake side to the exhaust between the lobes of the rotors and the outer wall and compressed by the backflow.

This can generate some vibrations, which bearings must be capable of withstanding.

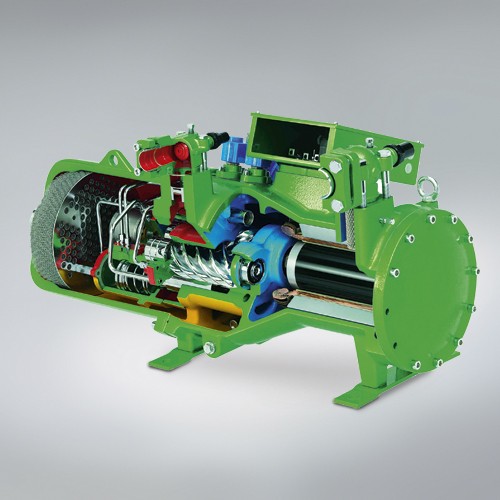

Two screws are used to compress gases. The gas enters on the inlet side and flows through the threads while the screws rotate. As the compression space becomes smaller, the gas is compressed.

This process requires bearings that can withstand high radial and axial loads and enable precise shaft positioning.

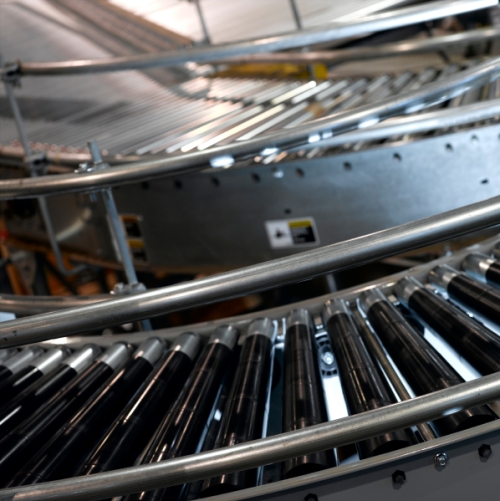

In the petrochemical industry, conveyor belt systems are often used to transport raw materials.

This places high demands on the bearings’ resistance to factors such as temperatures and contamination.

Ventilators are needed for a wide range of cooling processes.

In most cases, these involve high speeds and temperatures that can reach up to 200°C.

Electric drives for pumps, compressors, blowers and conveyor belt systems have to withstand high operating temperatures and high speeds.

Please select your options to view your contact.