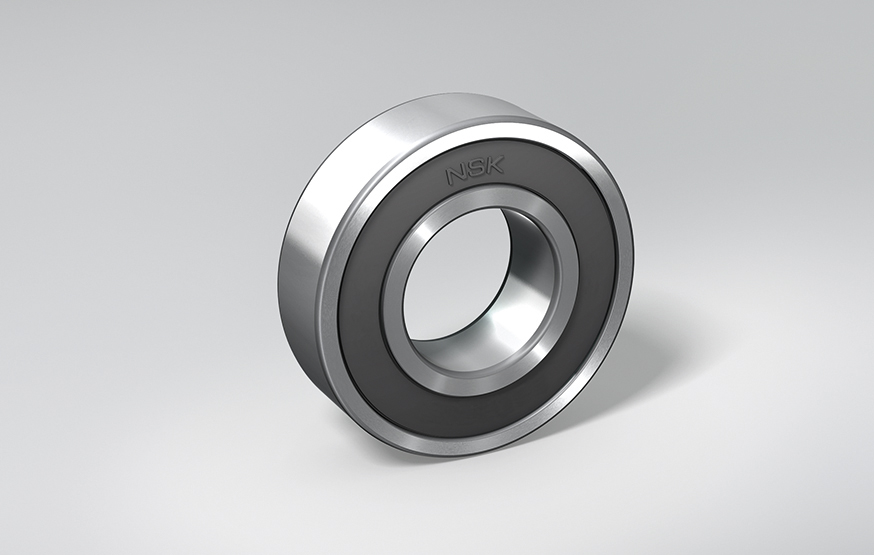

An important manufacturer of raw steel materials (strip and tubes) was facing issues with standard bearings, mounted in the welding station of a tube making machine. The high temperature of the welding area shortened the bearing life, breaking after short operation and causing continuous production stoppages for bearing replacement. The customer calculated a loss in production of 500 kg of tubes at every stoppage plus partial scrap of actual production. NSK proposed bearings for high temperature environments with special grease. With this solution the customer increased the bearing life. He also established preventive maintenance periods. All These measures led to increased productivity and Elimination of scrap.

| Before | Cost p.a. | NSK Solution | Cost p.a. | |

|---|---|---|---|---|

| 6 Bearings set x 15 replacements/year | € 180 | 6 Bearings set x 6 replacements/year | € 360 | |

| 1h downtime x 100€ labour cost x 15 replacements/year |

€ 1.500 | 1h downtime x 100€ labour cost x 6 replacements/year |

€ 600 | |

| Productivity loss of 1h x 15 replacements/year | € 7.500 | No costs | € 0 | |

| Total Costs | € 9 180 | € 960 | ||

Reference:SS-E-7027