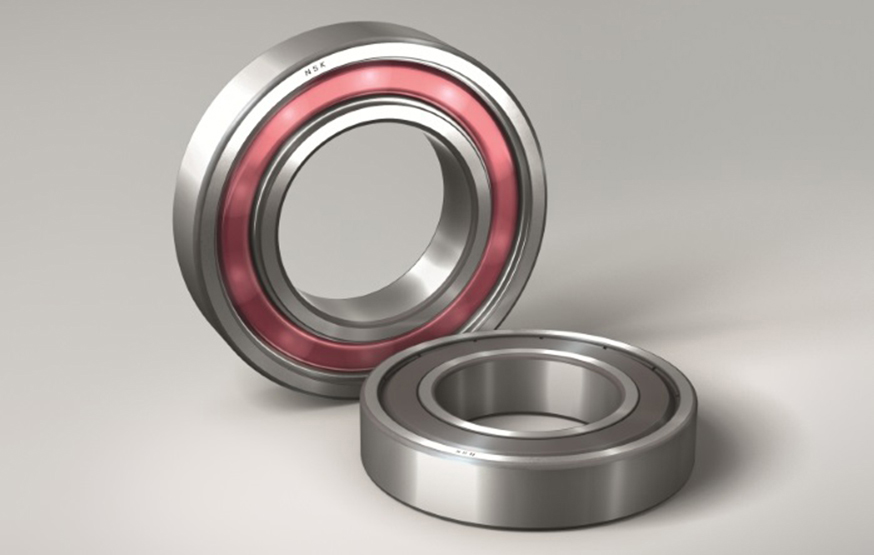

A German vegetable-processing company was experiencing repeated ball bearing failures on one of its transport systems. NSK was commissioned to investigate the problem. During the investigation it was determined that a large amount of water was entering the bearings and washing out the grease fill. Therefore, NSK suggested the use of sealed, corrosion-resistant Molded-Oil Bearings, thus increasing the bearing life from approximately 2 weeks to over 9 months.

| Before | Cost p.a. | NSK Solution | Cost p.a. | |

|---|---|---|---|---|

| Costs for Lubrication | € 6.377 | No Lubrication costs | € 0 | |

| Costs for mounting and dismounting the bearings | € 2.938 | No costs for mounting and dismounting of the bearings | € 0 | |

| Total Costs | € 9 315 | € 0 | ||

Reference:SS-E-1022