Important points for fitting and removal

Caution

Please use suitable personal protective equipment (PPE)

For model specific requirements, please follow car manufacturer installation instructions

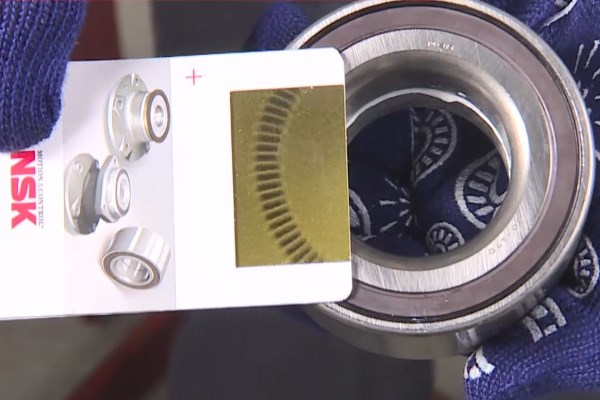

In this video the focus is on the first generation type wheel bearing with a magnetic encoder seal. The example shown here is for a front wheel bearing from a Toyota Corolla.

Tip: It is better not to use an impact wrench to avoid damage to the driven shaft

Tip: This helps to prevent damage to the drive shaft threads and is also a reason to discard the nut

Tip: In case the nut is rotating with the ball joint, press the ball joint further into the knuckle arm. The nut can now be loosened.

Tip: If you don’t have a dedicated tool as shown, or a ball joint splitter, do not hammer the ball joint directly. It is possible to hammer the end of the knuckle mounting arm lightly to loosen and remove the ball joint.

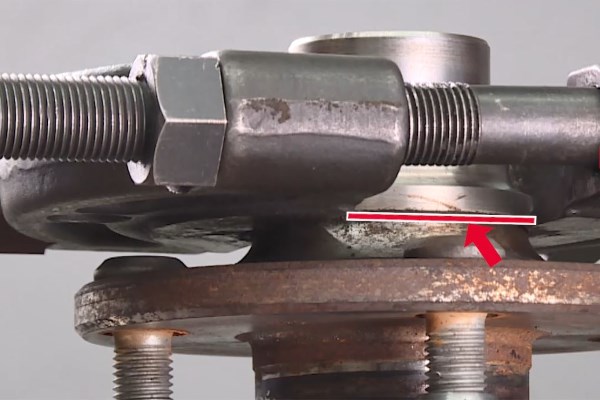

Tip: For safe removal ensure that there is enough contact between the end face of the inner ring and the separator.

Tip: Keep the inner ring to press out the bearing in the next step.

Tip: By cleaning the parts before assembly the mounting is less problematic and premature failure can be avoided.

Tip: Avoid any damage to the encoder surface

Tip: Only remove the bearing from its protective packaging immediately before the fitting

Tip: Do not put pressure on the encoder surface and keep it away from magnets or dirt.

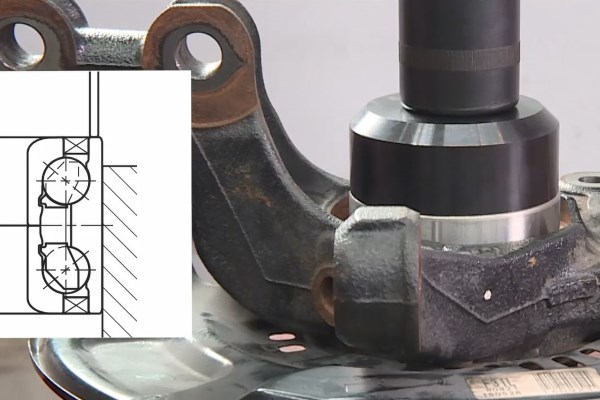

Tip: Outer diameter of tool < outer diameter of bearing.

Tip: Never press the inner ring to insert the bearing.

Tip: The gap in the snap ring should align with the sensor mounting hole on the knuckle.

Tip: Torque settings can vary significantly between car models. Therefore check the manufacturer values.

Tip: In case the nut is rotating with the ball joint, press the ball joint further into the knuckle arm. The nut can now be tightened.

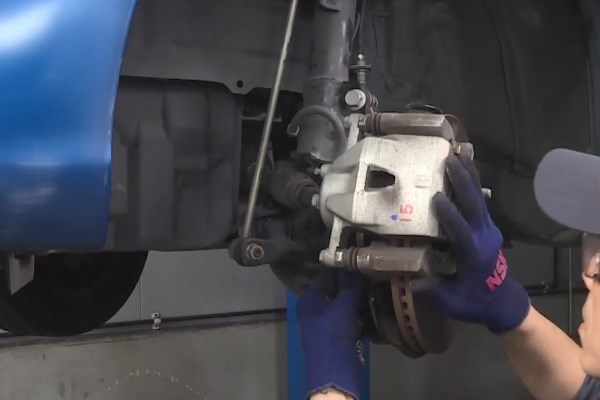

Tip: Ensure the brake hose has not be twisted or damaged.

Tip:

ProKIT is NSK's range for the Independent Automotive Aftermarket.

NSK ProKIT packages contain all components you need when replacing wheel bearings >>