NSK Products & Services for Machine Tools

From drilling and grinding to turning, bending, and milling, a vast range of demands is placed on the machine components used.

NSK quality components meet the special requirements for high speeds and acceleration while generating minimum noise and providing precise motion.

We offer the full package of expertise & engineering services, and have the right technical solution for your machine tool application, including precision ball bearings.

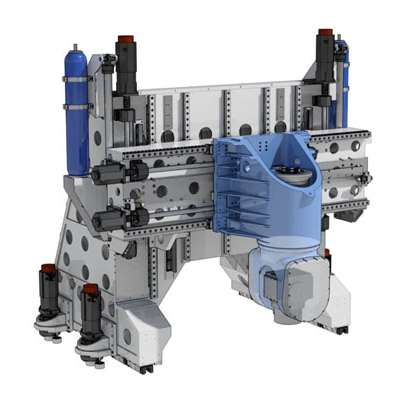

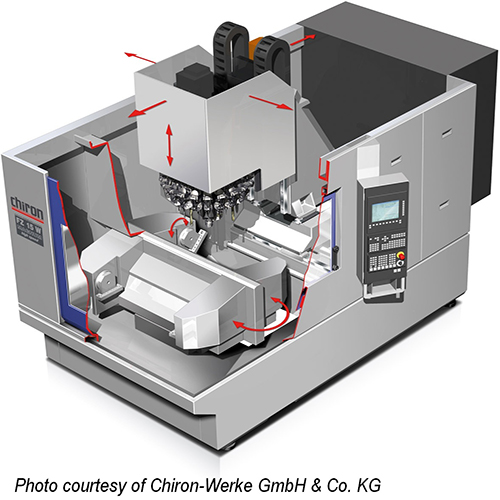

The RigiMill high-speed machining centre from Swedish manufacturer Modig holds the world record for high-speed milling. During an in-house exhibition, the machine removed 1001 cubic inches of chips or 16.4 litres of solid material in one minute. The Y and Z axes of the RigiMill feature twin drives with cooled HMD ball screws from NSK. Axial bearings and roller guide-ways for the axes are also supplied by NSK.

For machining centres in the aircraft and aerospace industries, chip removal speed is a key parameter because many of the central, very large components like wing ribs and other structural parts are milled from solid material. For example, parts weighing over 100 kg could be made from blocks of aluminium weighing 4 tonnes or more, which means that 97.5% of the material has to be removed.

Customers want maximum machining speed

Modig Machine Tool AB in Virserum, Sweden is well placed in the demanding field of high-speed machining for materials such as aluminium, titanium, steel and composites. The company, which was founded in 1947 by the grandfather of the current owner and CEO David Modig, develops and manufactures very high performance CNC machines that are used by aerospace manufacturers all over the world, including Airbus, Boeing, SAAB, Sikorsky and Volvo Aero. And while all Modig machines are reputed for their high speed and precision, the RigiMill gantry machine sets new standards in this regard.

“One of our goals was to develop the first 2-in-1 machine in this performance class; in other words a milling machine for high-speed roughing and finishing,” explains David Modig. “And the second goal: the RigiMill had to be the fastest milling machine in the world."

Stiffness as a requirement for accuracy

This goal was not an end in itself and the purpose was not to get an Olympic medal. David Modig says: “The aircraft industry is booming and manufacturers are continuously expanding their capacity, so we wanted to supply our customers with gantry systems that have even shorter machining cycles.” Machining the structural components of an aircraft also requires precision at the highest level, so the stiffness of the machine axes is just as important as speed, or even more so. The spindle of the RigiMill therefore uses twin drives on the Y and Z axes with a positioning accuracy of 0.5 μm in each case. The two electric motors work in master/slave mode.

“We only work with the best suppliers"

When selecting the linear drives for the axes, the decision was based not only on the technical specifications of the drive units, as David Modig explains: “We only work with the best suppliers. In this case we looked for a reputable supplier who had drive units with the highest accuracy, and the passion to support and promote innovative developments.”

With these criteria in mind, the choice was made in favour of NSK. And it was no surprise, because all previous models of Modig machining centres have been equipped with NSK drive components. In co-operation with Swedish authorised distributor Acumo, specialists from NSK in Ratingen configured the drive units, taking into account factors such as torque, speed, axis acceleration forces and the temperatures generated in the spindle drives during high-speed machining.

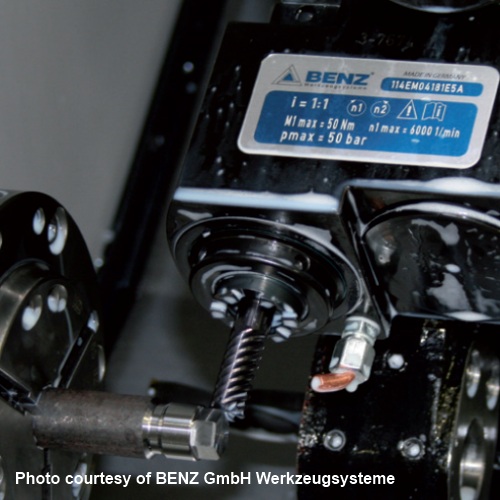

Ball screws for high-speed machining

Under these conditions, HMD series ball screws with nut cooling were found to be the optimal solution. The HMD series has been designed exclusively for use in high-speed machining applications, supporting travel speeds of up to 120 m/min. With a newly developed recirculation system, it was possible to increase the d x n speed rating to 160,000.

Nut cooling increases precision

Cooling the linear drive through the nut (precisely where the heat is generated), guards against temperature increases which could potentially impair the accuracy of machining.

To develop this linear drive with optimised cooling, NSK had to overcome a number of design challenges. For instance, the company’s specialists had to solve a problem caused by the cooling, which made the material in the body of the nut contract and affect the preload of the ball screw. After extensive tests, NSK development engineers came up with a cooling system whereby the preload level was not affected by the cooling at any time during operation.

From a single source: ball screws, bearings and roller guide-ways

Ball screws with nut cooling from the HMD series are used in the RigiMill’s Y and Z axes. The Y axis has a travel distance of 1560 mm, with 900 mm in the Z axis.

HMD ball screws are equipped with axial angular contact ball bearings from NSK’s BSBD series that were developed precisely for this type of application. The double-row configuration of these bearings, with a contact angle of 60°, is capable of withstanding high axial loads in both directions. They simultaneously offer the stiffness and accuracy required for modern precision machinery.

The NSK system solution is completed by RA roller guides in all the main axes of the RigiMill. They too, are characterised by extreme stiffness at maximum load capacity and create the conditions for the spindle axes to run smoothly, with low vibration in spite of the high speeds and high forces generated by machining. The ideal line contact of the roller keeps the displacement force low because a pure rolling movement adds no friction to the drive.

An impressive overall solution

“The components from NSK and the whole drive system meet the highly stringent requirements that we demand from our suppliers,” states David Modig. “They make a significant contribution to ensuring that the RigiMill not only works with the highest precision but also at extremely high speed, which in turn lowers machining times and cost per part.”

The RigiMill thus represents an economic solution from the customer's point of view, simply because it can produce more structural aerospace parts in a given time. Take the example of a wing rib, where the machining time of 384 minutes is reduced to only 74 minutes. In addition, when performing finishing, the machine can produce a surface quality of up to 0.8 Ra. Reactions from the company’s customers in the aircraft industry are equally positive.

David Modig says: “We've never had such good feedback from the launch of a new product series. Almost immediately, the RigiMill has found its place in the investment plans of major aircraft manufacturers and their suppliers.”

The world record that was set during a customer demonstration in October 2017 was surely a contributing factor. RigiMill removed 16.4 litres of solid material in just one minute. The spindle was running at speeds of up to 30,000 rpm driven by a 180 kW motor. After this impressive record was set, the first orders quickly arrived, which has led Modig to increase its manufacturing capacity in line with major aircraft manufacturers. A new production building is currently under construction.

As a system supplier, NSK offers linear guides, ball screws and super precision bearings .

During the design stage, our experienced application engineers help you to select the components that will enhance the energy efficiency, accuracy, and speed of your machine tools and thereby will boost your machine productivity.

Applying the special TF heat treatment achieves even longer life, expanding design possibilities for more compact and longer-lasting machines >>

NSK adds Ball Screws that accord with DIN standards widely used throughout Europe in a new lineup of standard stock ball screws >>

Even under unsettled conditions, the High-Durability Ball Screws show much better resistance to wear. Improved oil film reduces wear due to contact between balls and raceway groove >>

High speed and low noise Ball Screw Generation I offers peak noise reduction of at least 6 dBA over conventional ball screws. In Generation II, the speed has been increased at least 40% whereas the noise caused by the raceway has been reduced >>

Designed to meet the requirements of demanding applications: high accuracy, high rotational speed and high rigidity. These bearings deliver the highest level of accuracy, supported by our production capability, state-of-the-art equipment and extensive manufacturing expertise >>

Designed to achieve and deliver high-speed performance combined with high rigidity >>

Ball Screw Support bearings - designed to be compact, ready for easy & accurate installation, greased for life, with low friction and heat generation sealing. >>

This cage is applied to the NSKROBUST series of ultra-high speed angular contact bearings. Low NRRO, low heat generation and high-speed performance are achieved >>

High speeds, multi-shift or start/stop operations, high level of abrasive contamination use of coolants and lubricants, and a wide range of materials – NSK’s high-precision products excel by delivering unsurpassed finishing accuracy, even in these conditions. They enable ultra-high speeds, work extremely reliable and precise and are also quiet, meaning they tick all the boxes for optimum machining quality and cost-efficient solutions.

NSK’s patented new materials and components, extremely wear-resistant, further improve the performance of your machines.

The ROBUST range is primarily used for high speed applications, where robustness is required. With the medium ball size, the option of direct lubrication through the outer ring, our “Sursave” cage and the option for SHX steel, we have the right solution for your individual application >>

There are several sound arguments for maintaining a stable temperature below 40°C in ball screws to guarantee the utmost precision. This is because the fast motion of the nut raises the operating temperature and thereby prompts changes in running behaviour. A temperature increase of just 10°C causes a 1-metre-long spindle to stretch by 120 µm, which means that the machine tool can no longer deliver the necessary precision. Our specially developed nut cooling system drastically reduces heat generation, enabling consistent machining results. This means the necessary operating temperature can be maintained >>

NSK adds Ball Screws that accord with DIN standards widely used throughout Europe in a new lineup of standard stock ball screws >>

Modern grinding machines such as cylindrical, surface, tool and jig grinding machines are used to process a wide range of work pieces. They have to maintain very precise tolerances and roughness values. Over time, the lubricants and coolants used become contaminated. This causes severe abrasive wear to the machine’s components.

Compact, robust ball screws from the BSS series together with NSK’s innovative X1 seal concept ensure low-friction movements and high speed sealed ACBB make sure, that grinding machines run reliably. As a result, servicing intervals can be substantially extended, reducing maintenance costs.

High speed and low noise Ball Screw Generation I offers peak noise reduction of at least 6 dBA over conventional ball screws. In Generation II, the speed has been increased at least 40% whereas the noise caused by the raceway has been reduced >>

Even under unsettled conditions, the High-Durability Ball Screws show much better resistance to wear. Improved oil film reduces wear due to contact between balls and raceway groove >>

Reliable, high-precision motion products are needed for lathes turning machines to achieve the highest possible material throughput without downtime.

The high rigidity and load rating of NSK’s linear guides and precision bearings pave the way for a long service life, leading to enhanced productivity for your turning machines.

NSK adds Ball Screws that accord with DIN standards widely used throughout Europe in a new lineup of standard stock ball screws >>

Applying the special TF heat treatment achieves even longer life, expanding design possibilities for more compact and longer-lasting machines >>

Electrical discharge machines for high-precision applications require highly accurate mechanical components. NSK’s ball screws and the support bearings as well as the linear guides help to make the spark erosion process safe and are also ideal for high traverse rates. With their compact design, they are perfect for delivering precision in confined spaces.

Ultra-high load ratings, unique rigidity.

As the latest generation of roller guides, NSK’s RA series delivers outstanding motion accuracy. This is achieved by means of large rolling elements, ultra-high load ratings and rigidity. Meanwhile, the patented K1 lubrication unit enables long maintenance-free operation. Roller guides from the RA series also feature very low levels of vibration thanks to their specially constructed retaining and diverting components. This prevents the rollers from skewing >>

Even under unsettled conditions, the High-Durability Ball Screws show much better resistance to wear. Improved oil film reduces wear due to contact between balls and raceway groove >>

Demands for increasingly efficient energy conversion are leading to electromechanical drive concepts in various branches of industry. The process of metal manipulation – i.e., stamping, forming, and bending – has a major impact on how mechanical components are designed.

Linear guides, ball screws and bearings are replacing hydraulic drive solutions because they mobilise power reserves and help to significantly reduce driving axles. NSK’s cooled ball screws also increase the amount of heat which is transferred.

Typical machines using our products are Laser machines, bending, press brake, presses or punching.

Linear guides from the NH and NS series offer maximum precision combined with extremely high load ratings. Outstanding accuracy means that the object in motion is positioned precisely and moves optimally. It also guarantees smooth, even running >>

LPR/PR-Series has made a remarkable improvement in sealing performance. The LPR/PR-Series can be taken with or without maintenance-free NSK K1 lubrication unit >>

NSK offers a new series of ball screws where the nut and shaft can be combined freely with slight clearance. They are subject to DIN 69051 or ISO 3408 standards >>

The HTF-Series offers several types of Ball Screws for high-speed, high-load applications. >>

The NSKHPS TAC-series of Support Bearings for Ball Screws is available with a product lineup, as the bearings were improved by focusing on material cleanliness. >>

The series allow users to maintain high capacity performance with a smaller diameter of the screw shaft end. >>

Applying the special TF heat treatment achieves even longer life, expanding design possibilities for more compact and longer-lasting machines >>

NSK adds Ball Screws that accord with DIN standards widely used throughout Europe in a new lineup of standard stock ball screws >>

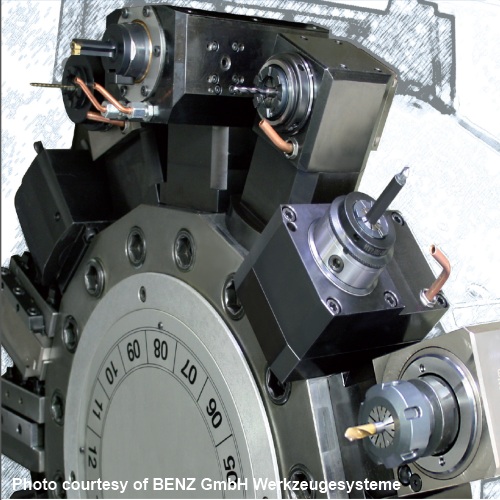

Spindles are at the heart of every machine and the bearing is the heart of the spindle. Therefore, the spindle manufacturer has to rely on the bearing’s quality and performance.

SHX is a heat-resistant & wear resistant steel resulting from NSK’s special proprietary materials & heat treatment technology; it offers unrivalled ultra high-speed performance and extended fatigue life ideally suited for machine tools running to their maximum capacity >>

NSK's oil-air lubrication works as a safe, economic and pollution free lubrication. With a lubricating hole (groove and hole in the outer ring) the lubricant quantity can be controlled and is injected precisely into the bearing, even under high speed. In addition this reduces the number of parts in the bearing and so simplifies the overall possible construction of the spindle >>

This cage is applied to the NSKROBUST series of ultra-high speed angular contact bearings. Low NRRO, low heat generation and high-speed performance are achieved >>

Sealed Angular Contact Ball Bearings are often required for driving tool applications. NSK ACBB are supplied with lifelong lubrication to ensure that no maintenance is needed – something which is essential in this context.

NSK's Sealed Angular Contact Ball Bearings ensure that the bearings are in the best possible condition, free of contamination, before and during operation while providing high level machining performance >>

Bearings have to withstand loads as well as high temperatures, multi-shift operation or start-stop operation. NSK’s angular-contact ball bearings are the ideal solution for machine tool turrets.

Total Quality Solution:

Standard spindle bearings, NSKHPS Angular-contact ball bearings, Tapered roller bearings, and Cylindrical roller bearings.

NSK Launched ACOUS NAVI™ Condition Monitoring & Diagnostic Software for FIELD System

ACOUS NAVI is a complete solution designed to monitor the operating status of machine components and detect or predict signs of damage or deterioration. It is provided to customers as an application that can be installed on a PC or as a pre-installed solution on dedicated hardware.

The ACOUS NAVI line-up includes three main versions to monitor and diagnose the status of bearings, ball screws, and linear guides.

https://www.acousnavi.nsk.com/en/

Please select your options to view your contact.