Condition Monitoring is a method to determine the condition of machines internal components such as bearings and gears whilst the machine is operating.

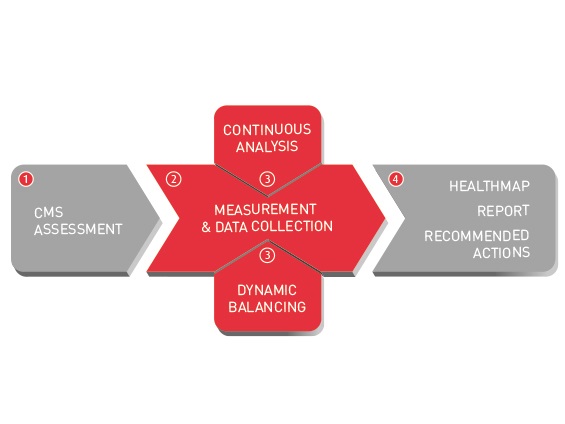

1. An initial survey using a scoring system to assess each machine and its suitability for CMS.

2. Modelling of the machinery on the NSK analysis software which determines the optimum monitoring points on the equipment.

3. Two measurement options:

4. Analysis and Reporting using the analysis software. An initial scan will grade each machine with a simple traffic light system (Healthmap). Machines that are highlighted “Orange” or “Red” are analysed in more detail using a specific analysing module.

Download our brochure "Condition Monitoring"

Please select your options to view your contact.