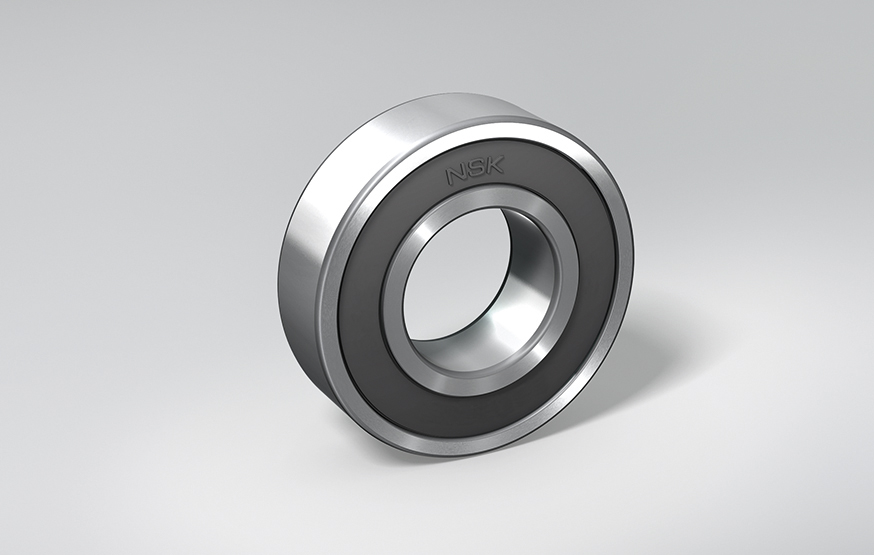

A wellknown tyre manufacturer had unexpected bearing failures on a conveyor belt during the tyre manufacturing. After only a few weeks of running, the conveyor bearings were damaged. An NSK Engineer analysed the bearing condition, revealing that open type bearings were installed allowing contamination to enter. NSK recommended to use sealed bearings with low torque in order to avoid additional loads. A trial was implemented and the recommended bearings significantly increased the lifetime of the bearings.

| Before | Cost p.a. | NSK Solution | Cost p.a. | |

|---|---|---|---|---|

| Mounting time 100 hours with hourly rate 80 € / hour 80 conveyors |

€ 8.000 | No mounting time necessary | € 0 | |

| Maintenance costs | € 5.000 | Maintenance costs reduced | € 0 | |

| Study & Report : equivalent to 10 hours of work | € 1.800 | Saving on study a report | € 0 | |

| Total Costs | € 14 800 | € 0 | ||

Reference:SS-E-3009