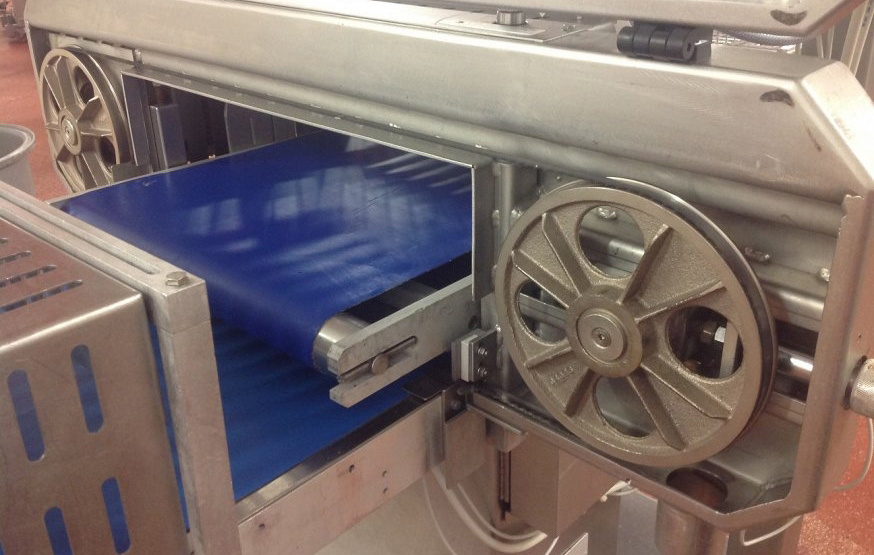

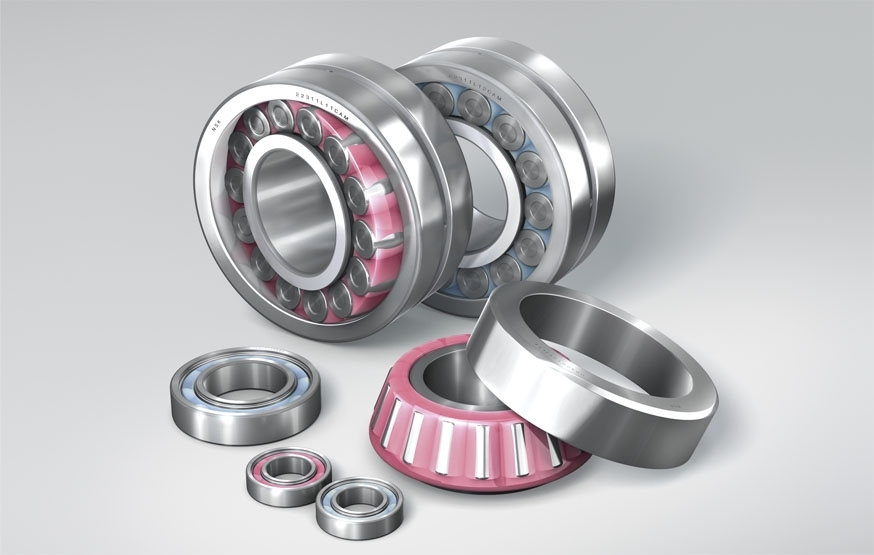

A customer was experiencing repeated bearing failures on their blade saw pulleys within the cake cutting units at their bakery. Approximately 20 bearing sets were changed annually and the bearings were failing every 4 to 6 weeks. Investigations by NSK showed the failures were caused by the ingress of water and hard particulates. NSK recommended replacing the standard bearings with NSK Molded-Oil units. A trial was implemented and since commissioning failures have been significantly reduced giving an extended life to 26 weeks, this has resulted in improved productivity and a cost saving.

| Before | Cost p.a. | NSK Solution | Cost p.a. | |

|---|---|---|---|---|

| Bearing costs | € 515 | Costs for NSK bearings with Molded-Oil | € 532 | |

| Labour costs | € 1.013 | No labour costs | € 0 | |

| Lost man hours | € 5.054 | No lost manpower costs | € 0 | |

| Blade & shaft replacement | € 3.321 | Blade & shaft replacement | € 47 | |

| Total Costs | € 9 903 | € 579 | ||

Reference:SS-E-2073