A paper mill in the US was facing frequent bearing failures on a Nip Roll. The bearing failed after just 1 year of service, which created a high cost of lost production together with significant maintenance issues.

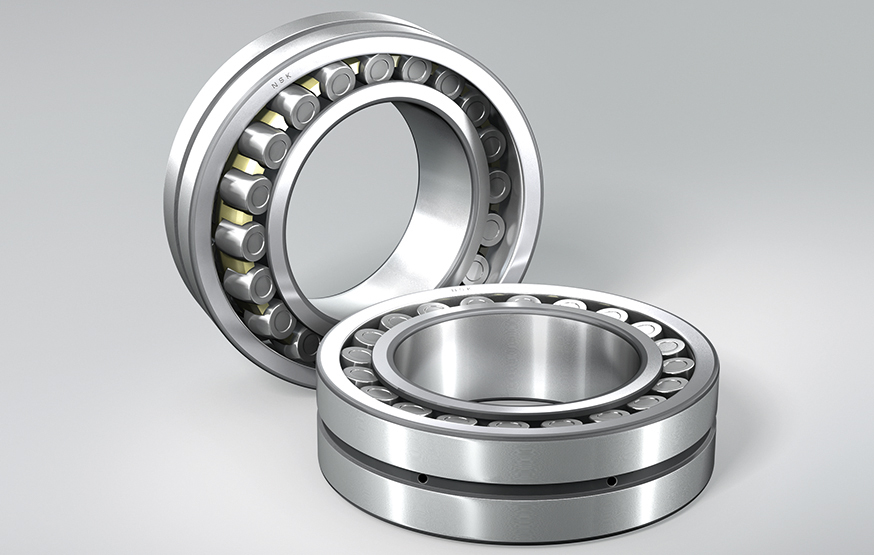

NSK was consulted to investigate and found out that the bearing design and set-up were not appropriate. After the installation of NSK's recommended Spherical Roller bearing, no more failures occured.

| Before | Cost p.a. | NSK Solution | Cost p.a. | |

|---|---|---|---|---|

| 12 hrs downtime per failure occuring 2-3 times per year @ cost of 20.000 € per hr | € 600 000 | No failures occured | € 0 | |

| Total Costs | € 600 000 | € 0 | ||

Reference:SS-E-0022