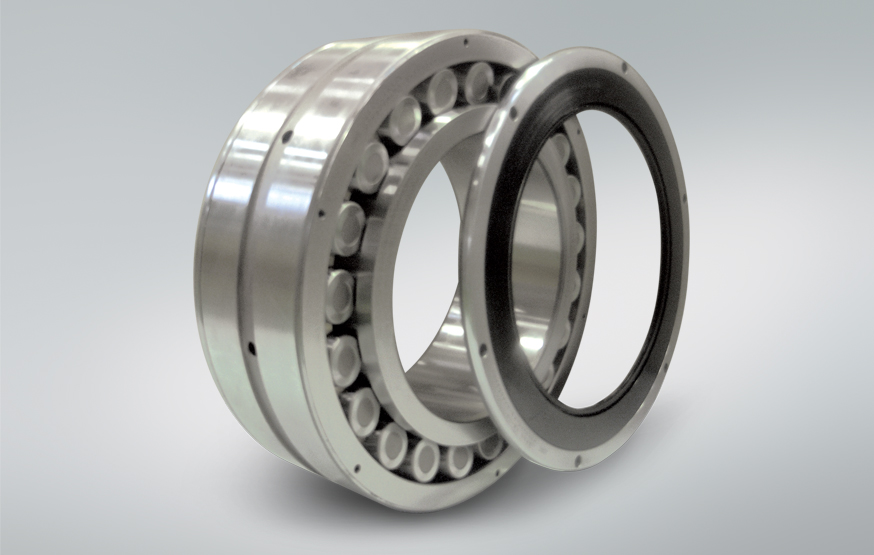

At an iron ore port facility in Australia, a bend pulley on a ship loading conveyor was determined to have only 6 months operating life before an exchange was determined to be necessary, due to heavy iron ore particle ingress and water contamination in the lubricant leading to short operating life. NSK Engineering designed a Spherical Roller Bearing for the ship loading conveyor application that offered the Hi-TF material solution and removable nitrile (HNBR) garter sprung seals to extend the operating life. Tough Steel is an effective countermeasure to the wear commonly found on the outer ring raceway, where the fixed load zone material wears under fine particle ingress.

| Before | Cost p.a. | NSK Solution | Cost p.a. | |

|---|---|---|---|---|

| Bearing Costs | € 3 511 | Bearing Costs | € 3 074 | |

| Costs of lost production | € 85 049 | Costs of lost production | € 28 350 | |

| Other Costs | € 30 607 | Other Costs | € 10 368 | |

| Total Costs | € 119 167 | € 41 791 | ||

Reference:SS-E-11-551