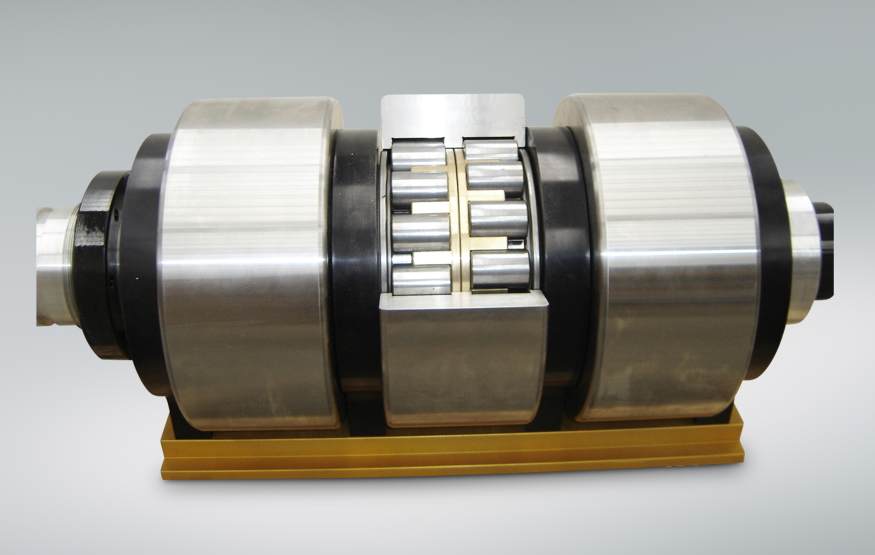

At a large German steelworks, the back-up rolls in a cold rolling mill continually failed after a short time. The purchasing department requested the use of competitor bearings for cost reasons. NSK checked the application and found out that the competitor bearings were running uneven after only a short period of use. NSK recommended to use back-up rollers, which can be reground several times. It is common that within this application bearings are turned and reground. The NSK bearings are now running for up to 1.5 years without any unplanned failures. Unplanned stoppages and maintenance cost have been reduced.

| Before | Cost p.a. | NSK Solution | Cost p.a. | |

|---|---|---|---|---|

| Bearing Costs | € 244 592 | Bearing Costs | € 134 296 | |

| Engineering Costs | € 7 200 | Engineering Costs | € 600 | |

| Costs of lost production | € 48 000 | Costs of lost production | € 4 000 | |

| Total Costs | € 299 792 | € 138 896 | ||

Reference:SS-E-1-1001