136 results

Industry: Wind Energy

Cost Savings: € 19 224

Product: NSK Deep Groove Ball Bearings

Industry: Steel and Metals

Cost Savings: € 35 600

Product: High Precision Angular Contact Ball Bearing

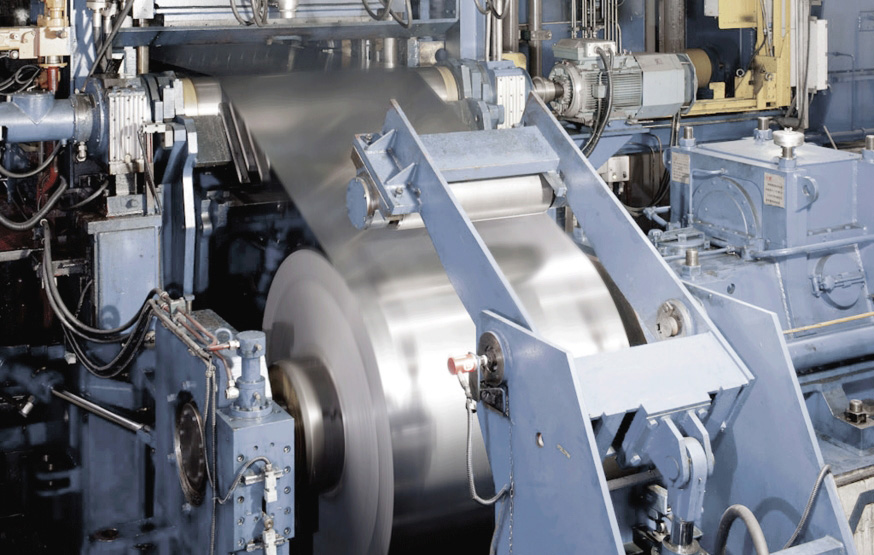

Industry: Steel and Metals

Cost Savings: € 17 450

Product: Condition Monitoring Service (CMS)

Industry: Steel and Metals

Cost Savings: € 154 000

Product: NSK 4-row Tapered Roller Bearings

Industry: Railway

Cost Savings: € 140 000

Product: AIP - Added Value Programme

Industry: Quarrying, Mining and Construction

Cost Savings: € 4 950

Product: Ball Sliders with K1 Lubrication Unit

Industry: Quarrying, Mining and Construction

Cost Savings: € 6 272

Product: Self-Lube® housing with triple lip seal bearing:

Industry: Power Generation

Cost Savings: € 134 040

Product: Spherical Roller Bearing with Brass Cage

Industry: Power Generation

Cost Savings: € 28 970

Product: Deep Groove Ball Bearings with DDU seals

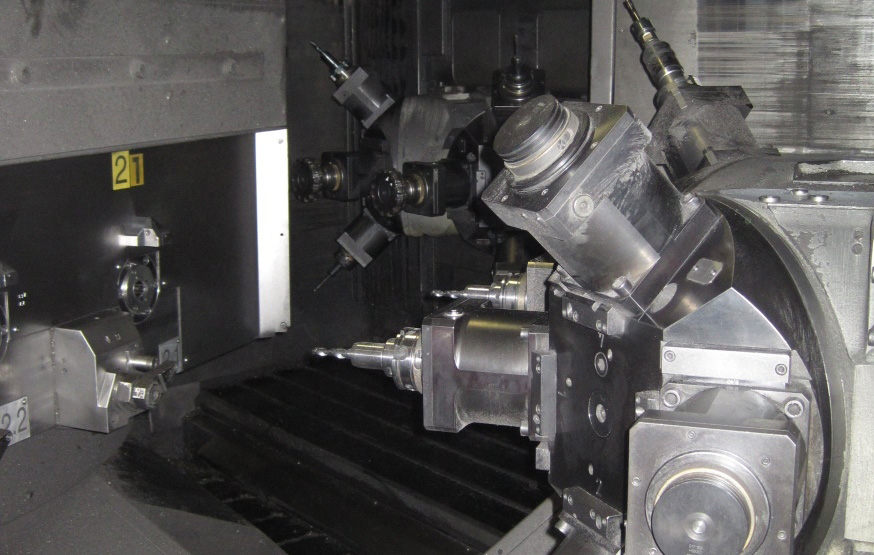

Industry: Machine Tools

Cost Savings: € 24 096

Product: Super Precision Bearings:

Industry: Machine Tools

Cost Savings: € 164 960

Product: Super Precision Angular Contact Ball Bearings

Industry: Food and Beverage

Cost Savings: € 27 263

Product: Cylindrical Roller Bearings - EW series

Industry: Food and Beverage

Cost Savings: € 63 300

Product: Silver-Lube Bearing Units

Industry: Cement

Cost Savings: € 51 476

Product: Angular Contact Ball Bearing with special HTF Steel

Industry: Automotive Production

Cost Savings: € 266 000

Product: Ball Screw with High-performance X1 Seal Design

Industry: Automotive Production

Cost Savings: € 50 406

Product: Sealed Super Precision Bearings: