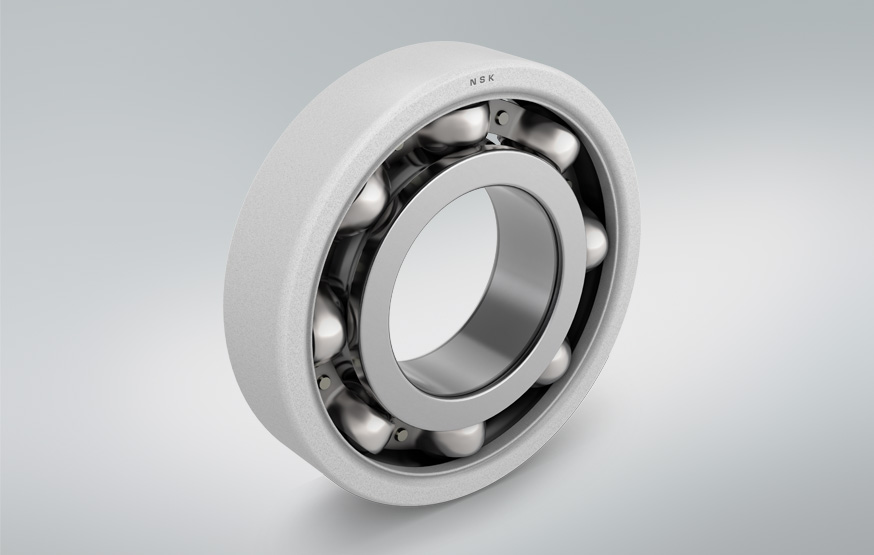

The end customer produces viscose fibers for a wide variety of applications, such as sanitary materials or tea bags. In an electric motor with a frequency converter, the bearings had to be replaced 6 times a year due to electrical corrosion. NSK recommended the use of current-insulated deep groove ball bearings. After that, there were no more unplanned failures. This drastically reduced the costs associated with production downtime.

| Before | Cost p.a. | NSK Solution | Cost p.a. | |

|---|---|---|---|---|

| Bearing Costs | € 384 | Bearing Costs | € 410 | |

| Engineering Costs | € 1 872 | Engineering Costs | € 312 | |

| Costs of lost production | € 18 000 | Costs of lost production | € 500 | |

| Lubrication Costs | € 50 | Lubrication Costs | € 50 | |

| Other Costs | € 9 000 | Other Costs | € 1 500 | |

| Total Costs | € 29 306 | € 2 772 | ||

Reference:SS-E-1-1048